Domestic Sewage Treatment PlantsDomestic sewage treatment plants are used in areas of the UK where mains drainage is inaccessible and provide a modern alternative to septic tank systems. Acting as an independent waste water treatment system, domestic sewage treatment plants are designed to receive all of the waste water from residential dwellings and promote the growth of Aerobic Micro-organisms which degrade the receiving waste water producing a treated effluent suitable for discharge to a natural watercourse.

There are various types of domestic sewage treatment plants available in the UK, but these all work on the same principle of developing Aerobic Micro-organisms which reduce the polluting load in the effluent, followed by settlement to remove any fine solids from the treated effluent. This treatment principle for waste water is the same as the principle used at main sewage treatment works for towns and cities, but on a reduced scale. Domestic sewage treatment plants have been available throughout the UK since the early 1980’s and are typically referred to as “packaged sewage treatment plants”. Over the last ten years there have been substantial advances in the design and manufacture of domestic sewage treatment plants. This together with more stringent regulations has resulted in sewage treatment plants being the preferred option over septic tanks systems for the disposal of waste water for rural locations.

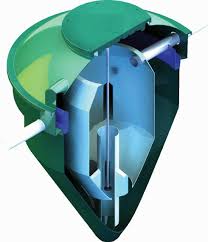

The majority of domestic sewage treatment plants are manufactured from GRP or Polypropylene, and typically are in the form of a ‘single tank’ system. The majority of domestic sewage treatment plants are also installed below ground having minimal impact on surroundings. There are a number of manufacturers of domestic sewage treatment plants in the UK with varying types of treatment processes to develop the required environment for the micro-organisms to strive. These include Biological Filters, Submerged Aerated Filters, Activated Sludge and RBC (Rotating Biological Contractor). The Clearwater sewage treatment plant is a ‘single tank’ system using a Biological Filter Process. Within the Clearwater system there are three treatment zones. Within the primary zone coarse solids are filtered and retained for gradual breakdown, whilst the resulting liquid is continuously distributed over a plastic biological suspended filter by an integral airlift, powered by a remote air blower. The biological filter is designed to promote the growth of aerobic micro-organisms which ‘treat’ the liquids. Within the final settlement zone fine solids settle to the floor leaving the resulting liquids to discharge from the system. Under normal conditions, treated water of 20mg/l BOD, 30mg/l S.S., 20mg/l Ammonia are discharged from the Clearwater system.

Clearwater domestic sewage treatment systems are available in a range of sizes – from a 2 bedroomed house up to a population of 18.

Features & Benefits

Sizing Clearwater domestic sewage treatment plants are available in three sizes. 1 - 6 people 7 - 12 people 13 - 18 people

Click here for further information on Clearwater Systems.

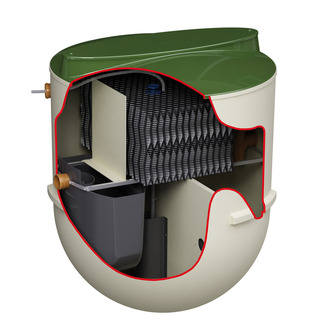

BioSure sewage treatment plants provide a discreet, reliable and affordable solution to sewage treatment for domestic and commercial premises without access to mains drainage. Providing a safe environment for the collection and treatment of waste water, BioSure produces a clear, odourless treated effluent suitable for discharge direct to a ditch, stream, or river. The Scientific Principle

Central to the operation of the BioSure sewage treatment plant is the biozone. Within the biozone aerobic micro-organisms develop through the use of fine bubble aeration and floating plastic media. This biozone process provides an extremely robust means of treating sewage, especially for reducing Ammoniacal Nitrogen (nitrogen which is present as ammonia). The third chamber is a final settlement zone where fine solids are separated and returned automatically to the first chamber using a recirculation airlift. The treated liquid is then suitable for discharge direct to a ditch or stream. The only electrical component within the smaller sizes of BioSure is a small air compressor. Biosure Selection BioSure sewage treatment plants are available in population equivalents of (PE) 6 – 55. When sizing a new sewage treatment plant the British Water Flows & Loads Code of Practice – 3 should be used. This Code of Practice provides the information required to ensure the correct size of treatment plant is installed.

Features & Benefits

Click here for further information on BioSure systems

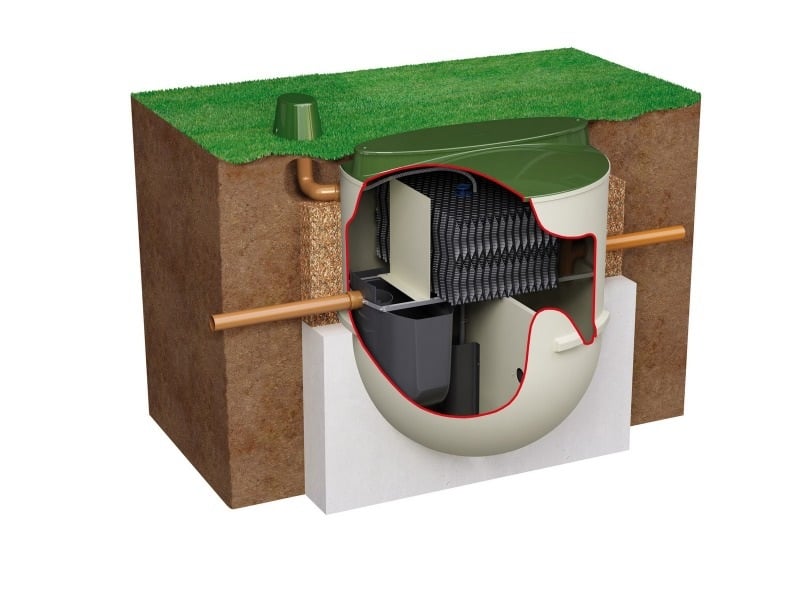

The Scientific Principle The Submerged Aerated Process is based on three phases, which takes place within three distinct compartments. The first compartment is a primary settlement zone where solids sink to the floor of the primary zone and allows the liquids to pass through to the second stage of the treatment process. Within the second compartment air is introduced into the submerged aerated filter producing the correct environment for aerobic micro-organisms to thrive. The third and final compartment is a final settlement zone where fine solids are separated and returned automatically to the first chamber using a recirculation airlift. The treated liquid is then suitable for discharge direct to a ditch or stream. Advantages Tricel sewage treatment plants are manufactured from one of the strongest glass reinforced plastic materials available and guarantees a robust and durable tank structure. The Tricel system also requires minimal excavation during installation due to its innovative design. Manufactured in population equivalents from 6 - 50, the Tricel system is available in ten different sizes and provides the flexibility of choosing a sewage treatment plant to cope with current or future loadings. Benefits

Domestic Sewage Treatment Plant Installers Mantair Contracts is an operating division of Mantair Limited, providing a professional service in the field of domestic sewage treatment plant installations.

Design We provide a free advisory service including no obligation site visits and assessments. During our visits our trained personnel inspect the existing drainage arrangements and identify the reasons for any occurring problems. Following our site assessment we provide a detailed description and quotations for the works involved. Delivery On the majority of projects the chosen domestic sewage treatment plant will be delivered to our offices and inspected prior to being approved for delivery. The sewage treatment plant is then delivered to site using one of our own transport vehicles to ensure the plant is delivered at the correct time to prevent any delays on site. Mantair holds a comprehensive inventory of sewage treatment plants, enabling most requirements to be fulfilled from stock. Installation Mantair engineers are accustomed to the correct handling and installation of all makes and models of sewage treatment plants. Our trained British Water Accredited engineers ensure that care is taken at all times during installation of the sewage treatment plant to negate the potential of any damage to either the treatment plant or the clients property.

For further information, click here or Freephone

© Mantair Limited 2011 |

Domestic sewage treatment plants will typically reduce the polluting load in the waste water by more than 95 percent, producing a clear and odourless effluent. In most instances this level of treatment will enable the effluent to be discharged to a ditch, stream or river after approval from the

Domestic sewage treatment plants will typically reduce the polluting load in the waste water by more than 95 percent, producing a clear and odourless effluent. In most instances this level of treatment will enable the effluent to be discharged to a ditch, stream or river after approval from the

The Tricel system is a complete sewage treatment plant based on Submerged Aerated Filter (SAF) Process. Aeration of waste water over a submerged media bed encourages the growth of aerobic micro-organisms which degrade the sewage, producing a final effluent suitable for discharge direct to a natural watercourse.

The Tricel system is a complete sewage treatment plant based on Submerged Aerated Filter (SAF) Process. Aeration of waste water over a submerged media bed encourages the growth of aerobic micro-organisms which degrade the sewage, producing a final effluent suitable for discharge direct to a natural watercourse.

The Mantair brand has been providing consumers with reliable, sustainable and economical drainage solutions for over two decades and continues to provide a professional service using modern technologies.

The Mantair brand has been providing consumers with reliable, sustainable and economical drainage solutions for over two decades and continues to provide a professional service using modern technologies.